How to protect Steel-Windows from rust – What’s the difference between Electrogalvanizing and Zinc Metalizing?

The main disadvantage of Steel Windows is the tendency to encounter rust at a certain point in time. Rusting (corrosion) is a natural and gradual process that affects iron due to exposure to water and oxygen in the air. The rust that forms on the iron makes it fragile and brittle, making it pretty destructive for products made of steel.

Israel”s Mediterranean climate is characterized by high temperatures, humidity, and the proximity to the sea which creates saltiness. These accelerate the rusting process, to a point when even products which underwent anti-rust procedures, such as painting or regular galvanization, eventually rust over the years.

How to prevent Rust on Steel products

Electrogalvanizing process

Zinc coating of Steel is called Galvanization. Zinc is a metal with electro-negative qualities as opposed to steel, so that it dramatically slows down rusting processes. The most common and inexpensive way to coat steel with zinc, is through a process called Electrolysis. The steel is “dipped” in a pool of water with dissolved zinc particles, at which point an electric current is passed through the steel. The electric attraction of the zinc ions “pin” them on to the steel.The main disadvantage of this technique is the relatively thin layer of coating.

Hot Galvanization

Zinc Metalizing using Spray-Flame Technique

Optimal Rust Protection for Steel-Windows

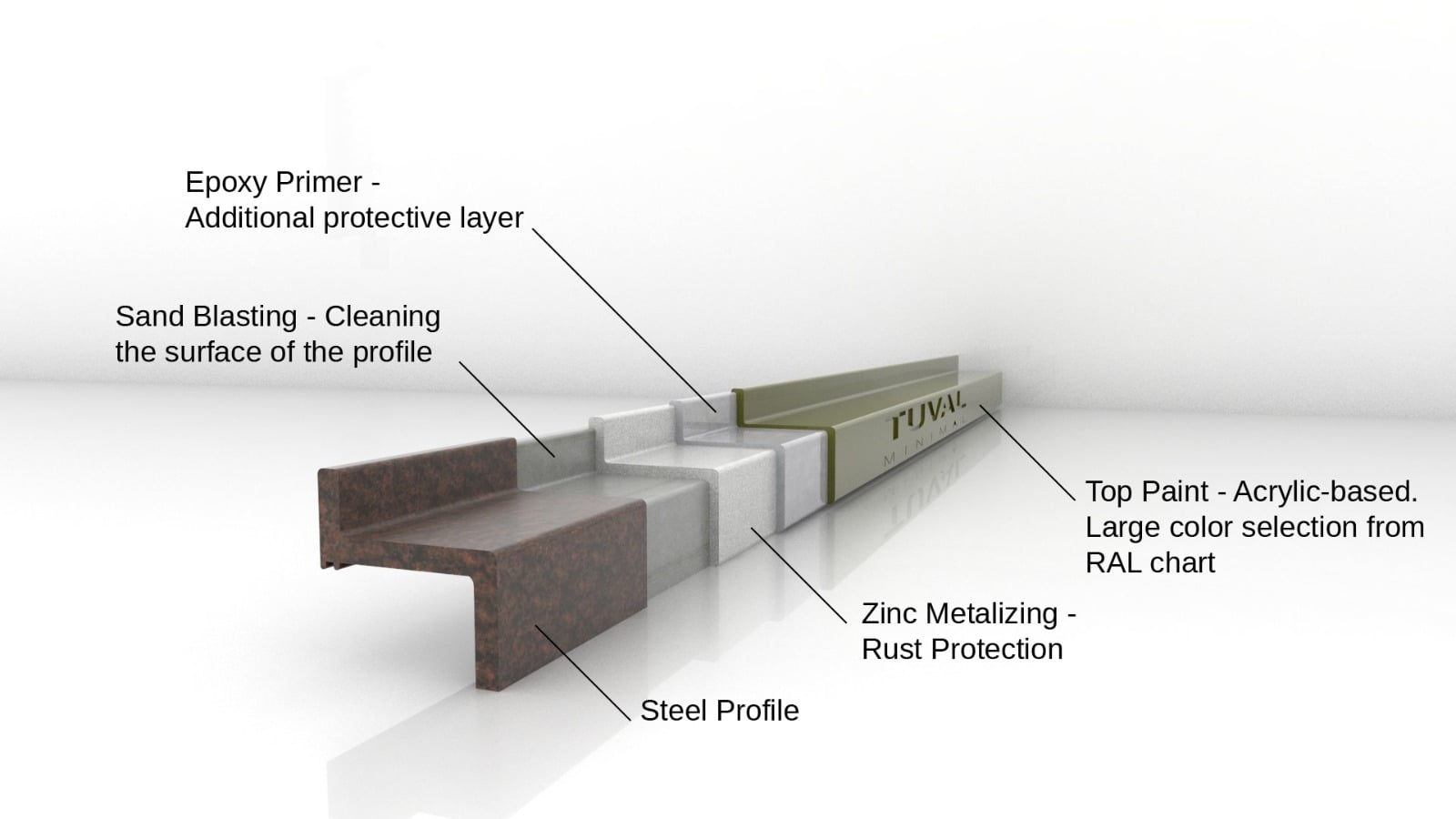

Tuval has successfully implemented the advanced Spray-Flame Galvanization method on all sorts of products. This unique technique provides Tuval Minimal’s Steel Frame products a crucial advantage compared to other manufacturers. Tuval’s Steel-Windows (along with all other products) are rust durable for many years, maintaining their clean and sleek look, even when installed in the most challenging areas: near the sea or in humid washrooms. The difference is very well felt when comparing Tuval’s White Windows with other bright products which underwent regular galvanization processes. This is mainly because on a bright surface, every spot of rust jumps out and is very apparent.

Along with the advanced galvanization method, Tuval “wet” paints with Epoxy primer & Acrylic top Paint, all of its products, as a second & Third layer of protection. When discussing Steel Windows manufactured using welding, This technique is significantly more efficient and qualitative as opposed to “powder” painting, and ensures the highest level of product finishing.

With our advanced galvanization method, Tuval promise you the highest finish quality of your Steel-Windows & Doors.

thermally insulated glass, a frame house, igu panels, thermally insulated glass, tuval minimal,steel window sliding, white steel windows

For further reading on Spray-Flame Hot Galvanization and its advantages: